Everything You Need To Know About Fashion’s Next-Gen Fabrics

[ Story ]

Article

Science is converging with almost everything we know — and the fashion industry is no exception. A pertinent challenge for fashion is the looming questions around textiles; its intensive production and subsequent waste that it generates. Globally, the fashion industry generates an estimated 92 million tons of textile waste each year, much of which ends up in landfills. Additionally, only about 12% of material used for clothing ends up being recycled, so our need for sustainable solutions in fabric production is critical. Science, like the beautiful force of expanding innovation that it is, continues to show immense promise in totally and radically shifting how we create textiles. We’re at the precipice of some incredible next-generation fabric solutions that make the intensive seed-to-crop-and-harvest processes of cotton and linseed seem totally archaic.

With multiple avenues of exploration at play, the fashion industry is advancing smart fabrication – a crucial next step in reshaping the fashion industry as it leverages advanced technologies to create fabrics that have enhanced features. Then,there’s bio-based materials, made from renewable resources like algae or agricultural byproducts, which are vital for decreasing the industry's reliance on petroleum-based textiles and lowering its carbon footprint.

Technology-led textile synthesis introduces innovative materials with enhanced properties, such as improved durability or greater sustainability, thus driving forward the evolution of fashion towards more ecologically conscious and performance-oriented solutions. Knowing firsthand how science and sustainability are incredible forces for change through our own development of bio-technological care solutions for fashion, we’re excited to share some other brands doing interesting things in the space.

Written by Holly Beaton / @hollybellb

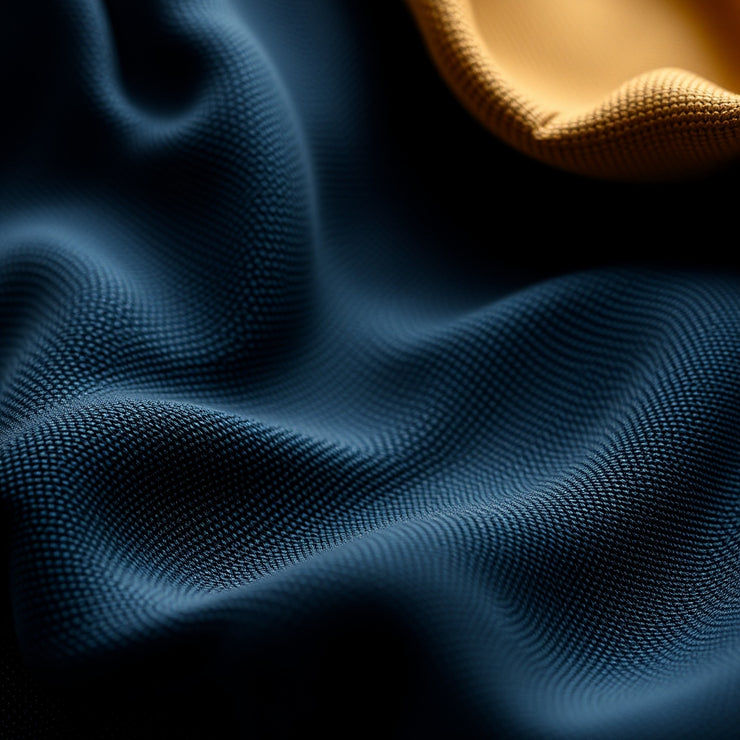

Spanish-based PYRATEX® is a company driving the latest vision for bio-based smart fabrication development. Their manifesto, summed up simply as ‘advancement through nature’, PYRATEX® is dedicated to seeing the world totally transition from synthetic textiles to natural and sustainable options, positioning itself as a trailblazer in textile innovation. The company develops cutting-edge materials using alternatives like seaweed-based fibres, agricultural byproducts, and recycled materials.

Critical to their research, fabrics are developed to preserve the inherent qualities of these fibres; so, they’re using everything from agricultural waste, to algae, in order to achieve smart fabrics that can offer wearers everything from infrared radiation reflection, UV protection, benefits to skin, cooling effects — antibacterial properties – and functional aspects like rapid drying. The list is exhaustive, and it's mind blowing.

Nature is our greatest scientist as demonstrated by the company, and everything PYRATEX® sets out to develop comes with its own ‘textile passport’, so buyers can fully validate the cost-to-planet that each fabric might have. Unlike many of the scaling issues faced by next-gen fabrics, PYRATEX® are one of the few spaces demonstrating the potential for mass-industry adoption, with some of their clients including ASICS, Ganni, Scotch & Soda, G-STAR RAW and many more.

Nature is our greatest scientist as demonstrated by the company, and everything PYRATEX® sets out to develop comes with its own ‘textile passport’, so buyers can fully validate the cost-to-planet that each fabric might have. Unlike many of the scaling issues faced by next-gen fabrics, PYRATEX® are one of the few spaces demonstrating the potential for mass-industry adoption, with some of their clients including ASICS, Ganni, Scotch & Soda, G-STAR RAW and many more.

OUTSIDE THE LAB

Fashion is also returning to the wisdom of fungi – with mycelium fabric, often referred to as mushroom leather, as another innovative next-gen fabric. Made from the intricate root and informational system of fungi, it offers a sustainable alternative to traditional leather, as it’s biodegradable and can be produced with minimal environmental impact. Mycelium fabric boasts qualities such as flexibility, strength, and a unique texture that mimics traditional leather. Mylium is a leading force in this space, with their transparency of process showcasing the deeply scientific (and almost alchemical) approach to creating fabrics. Their process of creating mycelium fabric begins with a pure culture of mycelium, which is introduced into a bioreactor, where it grows and multiplies in a nutrient-rich liquid medium. Natural binding agents are then added to the growing mycelium to strengthen its structure. The resulting mixture is mechanically shaped into sheets and dried to form a flexible textile. To refine its properties, the finished fabric is then treated with a specialised coating, enhancing qualities such as durability, water resistance, or texture, making it a versatile and regenerative alternative to traditional leather.

Then, there’s one of Japan’s leading biotech companies – Spiber — a space of dazzling, futuristic research and development. Onto a number of wildly innovative avenues in the realm of textiles and fabrication, their material science focuses on replicating natural protein evolution in the laboratory, a process that typically takes millions of years in nature. Through over 15 years of research and advanced biotechnology, they have developed Brewed Protein™, a cutting-edge material designed for both human use and environmental sustainability. This innovation involves precise DNA-level design to create protein polymers with diverse properties, aiming to provide advanced, ecologically conscious alternatives to traditional synthetic materials. Spiber's Brewed Protein™ materials, including fibres and films, are created through a fermentation process that involves brewing plant-based ingredients. This method uses microbial fermentation to produce protein polymers is a stunning example of what science is allowing us to achieve; literally, millions of years of natural protein evolution, into a simple yet daringly sophisticated scientific process, for the benefit of material future.

In truly leading circular fashion, Spiber’s technology is simultaneously pioneering metabolic recycling to transform biological waste into valuable raw materials. This process begins with breaking down discarded items, such as agricultural residues or natural fibres from old textiles, into fundamental nutrients like sugars and amino acids. These nutrients are then used in fermentation to produce new materials, including their Brewed Protein™ fibres. By integrating metabolic recycling into their production process, Spiber aims to contribute to a circular economy where products, whether bio-based or synthetic, are designed for complete recyclability at the end of their lifecycle. This approach reduces waste and supports the creation of sustainable materials that can be continuously reused and repurposed, through effective scientific processes.

Then, there’s one of Japan’s leading biotech companies – Spiber — a space of dazzling, futuristic research and development. Onto a number of wildly innovative avenues in the realm of textiles and fabrication, their material science focuses on replicating natural protein evolution in the laboratory, a process that typically takes millions of years in nature. Through over 15 years of research and advanced biotechnology, they have developed Brewed Protein™, a cutting-edge material designed for both human use and environmental sustainability. This innovation involves precise DNA-level design to create protein polymers with diverse properties, aiming to provide advanced, ecologically conscious alternatives to traditional synthetic materials. Spiber's Brewed Protein™ materials, including fibres and films, are created through a fermentation process that involves brewing plant-based ingredients. This method uses microbial fermentation to produce protein polymers is a stunning example of what science is allowing us to achieve; literally, millions of years of natural protein evolution, into a simple yet daringly sophisticated scientific process, for the benefit of material future.

In truly leading circular fashion, Spiber’s technology is simultaneously pioneering metabolic recycling to transform biological waste into valuable raw materials. This process begins with breaking down discarded items, such as agricultural residues or natural fibres from old textiles, into fundamental nutrients like sugars and amino acids. These nutrients are then used in fermentation to produce new materials, including their Brewed Protein™ fibres. By integrating metabolic recycling into their production process, Spiber aims to contribute to a circular economy where products, whether bio-based or synthetic, are designed for complete recyclability at the end of their lifecycle. This approach reduces waste and supports the creation of sustainable materials that can be continuously reused and repurposed, through effective scientific processes.

All this to say, we’re enamoured with this current moment in science, fashion and textiles — and our own focus at Sneaker LAB on conscious fashion care practices, backed by our bio-technological derived solutions, forms part of a stunning intermix between nature and all manner of bacteria, enzymes, technology and more — to encourage mindful approaches to fashion. As the fashion industry embraces these innovations, we are witnessing a change in the very materials that temper our lives (and wardrobes), and a fundamental reimagining of how we produce textiles; the future is more sci-fi than we can ever imagine, and it's unfolding before our very eyes.

[ Follow ]